-

Company

Introduction -

Product

-

Production &

Quality -

Contact Us

- HOME

- Production & quality

- Quality

Production & Quality

Quality

BionPak is ceaselessly putting in efforts for continuous advancement of the quality control system by executing analysis of the products

on the basis of the standards including USP, EP and KP, etc.

Tyvek® fabric specifications and standards

| Property | Test Method | Units | Tyvek®1073B | Tyvek®Asuron™ | Tyvek®1059B | Tyvek®2FS™ |

|---|---|---|---|---|---|---|

| Specification Properties * | ||||||

| Basis Weight* | ASTM D37761 DIN EN ISO 5361 |

oz/yd2 g/m2 |

2.20 (74.6) |

2.00 (67.8) |

1.90 (64.4) |

1.76 (59.5) |

| Delamination* | ASTM D27242 | lb/in. (N/2.54 cm) |

0.52 (2.3) |

0.56 (2.31) |

0.50 (2.2) |

0.61 (2.7) |

| Gurley Hill Porosity* | TAPPI T460 ISO 5636-5 |

sec/100 cc | 22 | 22 | 22 | 22 |

| Other Properties | ||||||

| Bendtsen Air Permeability | ISO 5636-33 | mL/min | 609 | 575 | 638 | 520 |

| Hydrostatic Head | AATCC TM 127 DIN EN 208114 |

in. H2O (cm H2O) |

59 (150) |

61 (155) |

56 (142) |

57 (145) |

| Tensile Strength, MD | ASTM D50355 DIN EN ISO 1924-25 |

lb/in. (N/2.54 cm) |

43.4 (193) |

38.1 (170) |

36.6 (163) |

35.1 (156) |

| Tensile Strength, CD | ASTM D50355 DIN EN ISO 1924-25 |

lb/in. (N/2.54 cm) |

46.8 (208) |

44.4 (198) |

39.2 (174) |

35.3 (157) |

| Elmendorf Tear, MD | ASTM D1424 DIN EN 21974 |

lb (N) |

0.77 (3425) |

0.87 (3872) |

0.67 (2980) |

0.63 (2.8) |

| Elmendorf Tear, CD | ASTM D1424 DIN EN 21974 |

lb (N) |

0.79 (3514) |

0.99 (4406) |

0.72 (3203) |

0.83 (3.7) |

| Mullen Burst | ASTM D774 ISO 2758 |

psi (kPa) |

178 (1227) |

153 (1054) |

153 (1055) |

134 (925) |

| Thickness | ASTM D17776 DIN EN 205347 |

mils (μm) |

7.3 (185) |

7.1 (180) |

6.5 (165) |

6.11 (155) |

| Opacity | TAPPI T425 ISO 24718 |

% | 92.4 | 96.9 | 90.7 | 94.3 |

| Miscellaneous Properties | ||||||

| Microbial Barrier | ASTM F1608 | Log Reduction Value (LRV) |

5.2 | 4.7 | 4.7 | 3.2 |

| Elongation, MD | ASTM D50355 DIN EN ISO 1924-25 |

% | 22 | 20 | 21 | 23 |

| Elongation, CD | ASTM D50355 DIN EN ISO 1924-25 |

% | 26 | 24 | 26 | 28 |

| Thickness Range | ASTM D17776 DIN EN 205347 |

mils (4 sigma) (μm) (4 sigma) |

3.5–11.1 (89–282) |

3.2–10.9 (81–277) |

2.9–10.1 (74–257) |

2.8–9.1 (70–230) |

| Spencer Puncture | ASTM D34209 | in-lb/in2 (J/m2) |

43 (7488) |

41 (7141) |

35 (6195) |

28 (4900) |

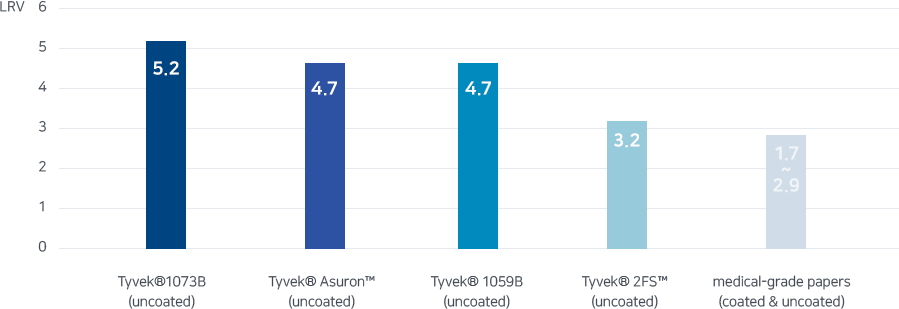

Tyvek® microbial barrier test results

Per ASTM F1608. Microbial barrier is the measure of the ability of a porous substrate to prevent bacteria penetration. A completely impermeable control sample (microbial penetration is zero) is challenged with one million or 106 colony. forming units (cfu). The number of cfu 106 has a log10 value of 6. If a sample challenged in the same way as the control allows 10 cfu (log 10=1) to penetrate, then its log reduction value (LRV) is 5 (6–1=5). Therefore, the higher the LRV, the more resistant the packaging is to bacteria and microorganisms.

SEM photo of Tyvek® fabric

The unique structure of Tyvek®, which creates a tortuous path with substantial lateral movement, results in superior microbial barrier properties.

-

Top view of Tyvek®

Top view of Tyvek®

(200x magnification) -

Cross-sectional view of Tyvek®

Cross-sectional view of Tyvek®

(500x magnification)