-

회사소개

-

제품

-

생산 및 품질

-

Contact Us

- HOME

- 생산 및 품질

- 품질

Production & Quality

품질

바이온팩은 USP, EP, KP 등의 기준을 토대로 제품에 대한 분석을 진행하며

품질 관리 시스템의 지속적인 발전을 위해 끊임없이 노력합니다.

Tyvek® 원단 사양 및 규격

| Property | Test Method | Units | Tyvek®1073B | Tyvek®Asuron™ | Tyvek®1059B | Tyvek®2FS™ |

|---|---|---|---|---|---|---|

| Specification Properties * | ||||||

| Basis Weight* | ASTM D37761 DIN EN ISO 5361 |

oz/yd2 g/m2 |

2.20 (74.6) |

2.00 (67.8) |

1.90 (64.4) |

1.76 (59.5) |

| Delamination* | ASTM D27242 | lb/in. (N/2.54 cm) |

0.52 (2.3) |

0.56 (2.31) |

0.50 (2.2) |

0.61 (2.7) |

| Gurley Hill Porosity* | TAPPI T460 ISO 5636-5 |

sec/100 cc | 22 | 22 | 22 | 22 |

| Other Properties | ||||||

| Bendtsen Air Permeability | ISO 5636-33 | mL/min | 609 | 575 | 638 | 520 |

| Hydrostatic Head | AATCC TM 127 DIN EN 208114 |

in. H2O (cm H2O) |

59 (150) |

61 (155) |

56 (142) |

57 (145) |

| Tensile Strength, MD | ASTM D50355 DIN EN ISO 1924-25 |

lb/in. (N/2.54 cm) |

43.4 (193) |

38.1 (170) |

36.6 (163) |

35.1 (156) |

| Tensile Strength, CD | ASTM D50355 DIN EN ISO 1924-25 |

lb/in. (N/2.54 cm) |

46.8 (208) |

44.4 (198) |

39.2 (174) |

35.3 (157) |

| Elmendorf Tear, MD | ASTM D1424 DIN EN 21974 |

lb (N) |

0.77 (3425) |

0.87 (3872) |

0.67 (2980) |

0.63 (2.8) |

| Elmendorf Tear, CD | ASTM D1424 DIN EN 21974 |

lb (N) |

0.79 (3514) |

0.99 (4406) |

0.72 (3203) |

0.83 (3.7) |

| Mullen Burst | ASTM D774 ISO 2758 |

psi (kPa) |

178 (1227) |

153 (1054) |

153 (1055) |

134 (925) |

| Thickness | ASTM D17776 DIN EN 205347 |

mils (μm) |

7.3 (185) |

7.1 (180) |

6.5 (165) |

6.11 (155) |

| Opacity | TAPPI T425 ISO 24718 |

% | 92.4 | 96.9 | 90.7 | 94.3 |

| Miscellaneous Properties | ||||||

| Microbial Barrier | ASTM F1608 | Log Reduction Value (LRV) |

5.2 | 4.7 | 4.7 | 3.2 |

| Elongation, MD | ASTM D50355 DIN EN ISO 1924-25 |

% | 22 | 20 | 21 | 23 |

| Elongation, CD | ASTM D50355 DIN EN ISO 1924-25 |

% | 26 | 24 | 26 | 28 |

| Thickness Range | ASTM D17776 DIN EN 205347 |

mils (4 sigma) (μm) (4 sigma) |

3.5–11.1 (89–282) |

3.2–10.9 (81–277) |

2.9–10.1 (74–257) |

2.8–9.1 (70–230) |

| Spencer Puncture | ASTM D34209 | in-lb/in2 (J/m2) |

43 (7488) |

41 (7141) |

35 (6195) |

28 (4900) |

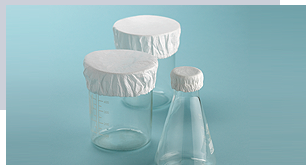

Tyvek® 미생물 장벽 테스트 결과

Per ASTM F1608. Microbial barrier is the measure of the ability of a porous substrate to prevent bacteria penetration. A completely impermeable control sample (microbial penetration is zero) is challenged with one million or 106 colony. forming units (cfu). The number of cfu 106 has a log10 value of 6. If a sample challenged in the same way as the control allows 10 cfu (log 10=1) to penetrate, then its log reduction value (LRV) is 5 (6–1=5). Therefore, the higher the LRV, the more resistant the packaging is to bacteria and microorganisms.

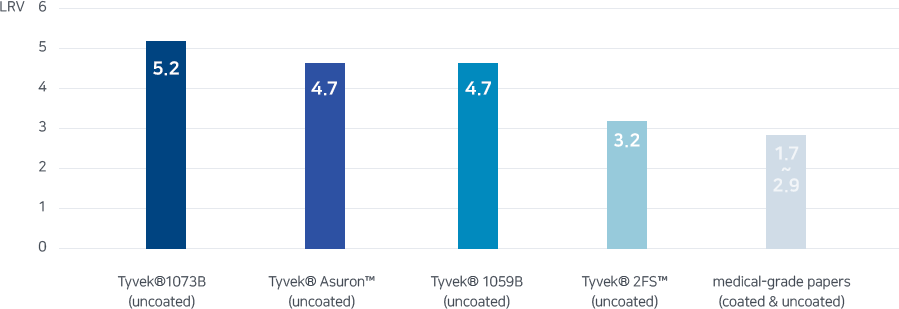

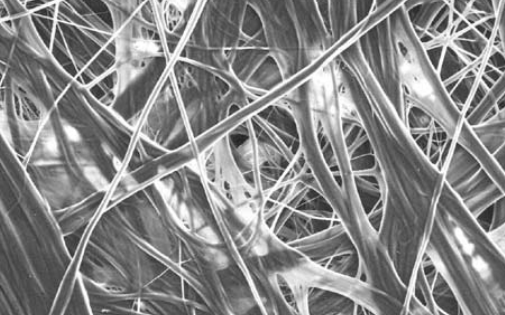

Tyvek® 원단 SEM 사진

The unique structure of Tyvek®, which creates a tortuous path with substantial lateral movement, results in superior microbial barrier properties.

-

Top view of Tyvek®

Top view of Tyvek®

(200x magnification) -

Cross-sectional view of Tyvek®

Cross-sectional view of Tyvek®

(500x magnification)